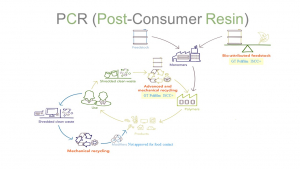

After obtaining the ISCC + certification in September 2021, the first Italian company in the flexible pavkaging sector, GT Polifilm has produced one of the first recycled polypropylene packaging suitable for food contact made with 30% resins recycled deriving from the valorisation of plastic waste (PCR – Post Consumer Resins).

Although, still in the start-up phase, the chemical recycling processes (pyrolysis of plastic waste) are used to generate resins approved for primary packaging and suitable for contact with food.

Chemical recycling processes are extremely promising because the packaging produced has not any impact on the efficiency of the entire supply chain as the recycled coextruded polypropylene film is identical to the virgin one (no further approval tests are necessary, no changes to the process parameters of the packaging machines are necessary and the shelf life of the product is guaranteed). The process guarantees a real circular economy and the reduction of greenhouse gas emissions by limiting the dependence on fossil reserves

Soon GT Polifilm will amaze you with other solutions that are more environmentally friendly than traditional packaging without losing supply chain and packaging efficiency and efficacy.

Reliability, transparency, customer and consumer protection and superior quality are in the company’s DNA This values guide the policies of GT Polifilm without any compromise.

For more information, do not hesitate to contact us.